Identify Problems at the String Level to Secure Contractual Warranties

This case study presents the successful implementation of an automated solution to calculate and notify asset managers on a weekly basis of a list of strings with their availability, identifying disconnections and ranking them from lowest to highest availability. In addition, the performance of each string is compared with the performance guaranteed by the panel manufacturer, strings with associated combiner boxes and inverters are identified to facilitate rapid troubleshooting on site, and operator response time is measured. This solution has significantly improved operational efficiency and warranty management across a portfolio of five PV plants averaging 18MW.

CONTEXT

The client, an Independent Power Producer (IPP), managed a portfolio of five PV plants under contractual warranty. Identifying and addressing issues with disconnections, installed panel performance and warranty compliance was essential to optimise power generation and maximise revenue.

CHALLENGES

The client faced the following challenges:

- Manual Analysis: Manual downloading of data at string level and subsequent analysis in MS Excel was

inefficient, time consuming and limited processing, analysis and problem detection capabilities. - Warranty Management: The lack of an automated analytic tool made it difficult to identify and document performance problems with installed panels that could lead to warranty claims.

- Operational Efficiency: The lack of an automated system and reliance on manual analysis affected the ability to detect and resolve problems.

SOLUTION

Quintas Analytics developed and implemented a comprehensive solution to address the above challenges:

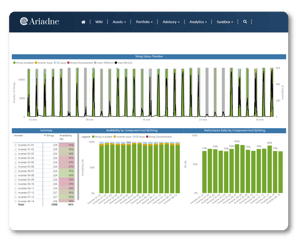

- Centralised Analysis Platform: A platform was created that collected and processed string availability and performance data at the lowest granularity.

- Calculation of Availability and Performance: Algorithms were implemented to calculate the availability of strings and compare their performance with the values guaranteed by the manufacturers of the PV panels installed at the plant.

- Identification and Classification: The solution automatically disconnected the strings, sorted them by percentage of availability and performance and linked each string to its combiner box and inverter, allowing the problem to be quickly located on site.

- Automatic Notifications: We set up weekly notifications for asset managers, providing a list of strings with associated availability, performance and location details.

- Resolution Time Metrics: The solution recorded the operators' resolution times for identified issues, allowing them to gauge and

improve operational efficiency.

RESULTS AND BENEFITS

Implementing the solution had a positive impact on operational management and enforcement of the contractual guarantee:

1. Automation and Efficiency: The automated solution replaced the manual process in MS Excel, saving time and improving the efficiency and analysis capacity of the management team.

2. Warranty Compliance: Comparison with the performance standards guaranteed by PV panel manufacturers allowed for the early identification of problems and more effective warranty management.

3. Optimised Power Generation: Rapid identification of disconnected strings and other performance issues contributed to improving asset power generation.

4. Informed Decision Making: The sorting, identification and location of problematic strings streamlined the maintenance decisions process and made for better informed choices.

5. Improved Operations: Recording operator response times encouraged faster reactions and continuous improvement.

CONCLUSIONS

The solution implemented for the analysis of string availability and performance in a portfolio of five PV plants proved to very successful in improving asset management and the administration of contractual guarantees. The automation of the process and the calculation of time-to-resolution metrics provided essential tools for effective and profitable management. This solution sets a valuable example for the management of similar projects in the field of solar PV.