Monitor the Temperature of Transformers to Avoid Unexpected Shutdowns

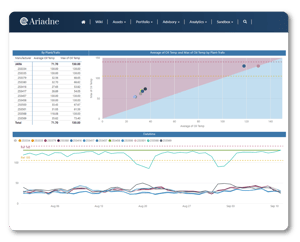

This case study presents the successful implementation of an automated solution to collect daily average transformer oil temperature data for a total of 420 transformers installed in a portfolio of 150 PV assets. The solution compares the average temperatures with reference values set by the asset manager and notifies the asset manager of transformers whose temperatures exceed the set limit. This solution has improved the early detection of oil temperature-related problems in transformers, reducing the risk of malfunction and optimising the availability and profitability of the portfolio.

CONTEXT

The customer, a leading renewable energy company, managed a portfolio of 150 PV assets with multiple transformers at each plant. Early detection of transformer temperature problems was crucial for avoiding unplanned outages and ensuring profitability.

CHALLENGES

The client faced the following challenges:

- Complex Monitoring: Manually monitoring the temperatures of numerous transformers at 150 assets via SCADA values was a complicated and tedious process.

- Early Detection: Early detection of abnormal temperatures was difficult, increasing the risk of such anomalies leading to availability problems.

- Timely Notifications: There was no effective system for notifying the asset manager of transformers with abnormal temperatures, making it difficult to effectively prioritise the management of unavailability risks.

SOLUTION

Quintas Analytics developed and implemented a complete automated solution to address the challenges mentioned above:

- Temperature Data Collection: A system was designed to automatically collect information from SCADA concerning average oil temperatures.

- Comparison with Reference Values: The solution compared daily average temperatures with the threshold reference values set by the asset manager.

- Automatic Notifications: If the reference value was exceeded, the solution sent a notification to the manager with a list of affected transformers, sorting them by those with the highest temperatures.

RESULTS AND BENEFITS

Implementing the solution had a positive impact on the portfolio's operational readiness and profitability:

1. Early Detection: Automation enabled with early detection of temperature problems in transformers, preventing malfunctions that would otherwise affect the overall availability of the asset.

2. Risk Reduction: The solution minimised the risk of unplanned outages and costly downtime.

3. Optimising Profitability: Improved availability contributed to the overall profitability of the portfolio.

4. Efficient Operations: The management team was able to focus on proactive action plans to mitigate the risk rather than waiting for actual unavailability caused by transformer problems.

CONCLUSIONS

The implemented solution for automated temperature monitoring of transformers in a PV portfolio proved a success story regarding improved availability and profitability. Process automation, data collection and automatic notifications provided essential tools for effective and preventive management. This solution sets a valuable example for the management of similar projects in the field of solar energy and maintenance of critical components.